Pob zeb diamond xaim txiav tshuab yog tseem hu ua kev sib sau ua ke cov thev naus laus zis. Nws yog kev siv electroplating lossis resin sib txuas lus ntawm pob zeb diam hlau, pob zeb diamond hlau ncaj qha ua si ntawm silicon pas nrig lossis silicon Ingot los tsim cov nyhuv sib tsoo, kom ua tiav cov txiaj ntsig ntawm kev txiav. Pob zeb diamond hlau txiav muaj cov yam ntxwv ntawm kev txiav ceev ceev, siab txiav qhov tseeb thiab cov khoom qis.

Tam sim no, lub lag luam siv lead ua lag luam rau pob zeb diamond hlau tej silicon wafer tau tag nrho cov txheej txheem ntawm cov teeb meem dawb yog qhov teeb meem feem ntau. Hauv kev pom ntawm no, daim ntawv no tsom rau yuav ua li cas tiv thaiv pob zeb diamond xaim txiav monocrystalline Silicon Wafer Velvet Cov teeb meem dawb.

Cov txheej txheem ntxuav ntawm pob zeb diamond xaim txiav monocrystalline silicon wafer yog kom tshem tawm cov kab hlau tawm, tshem cov roj hmab sawb, thiab ntxuav cov roj hmab wafer. Cov cuab yeej ntxuav tau tsuas yog siv lub tshuab ntxuav ua ntej (degumming tshuab) thiab lub tshuab ntxuav. Lub ntsiab tu cov txheej txheem ntawm lub tshuab ntxuav ua ntej yog: noj-txau-txau-ultrasonic tu-degumming-huv si dej-underfing-underfing. Lub ntsiab tu kev tu huv yog: pub-ntshiab dej-alkali ntxuav-dawb paug dej-ua ntej-qhuav dej (qeeb lifting-pub mis.

Lub hauv paus ntsiab lus ntawm ib leeg-crystal velvet ua

Monocrystalline silicon wafer yog tus yam ntxwv ntawm anisotropic corrosion ntawm monocrystalline silicon wafer. Cov yeeb ncuab cov kev cai yog cov tshuaj tiv thaiv kev cai hauv qab no:

Si + 2Nsoh + h2o = na2sio3 + 2h2 ↑

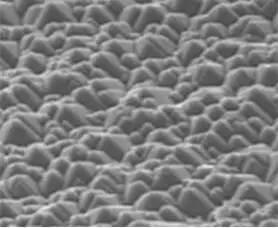

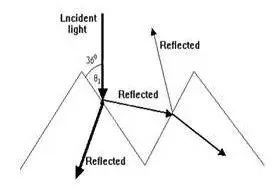

Nyob rau hauv essence, lub suede ua txheej txheem yog: Naau daws teeb meem sib txawv ntawm cov crystal ceev tshaj (111), yog li (nws thiaj li tsim nyob rau saum npoo rau (111) Plaub-tog cooke, uas yog "qauv" qauv (raws li qhia hauv daim duab 1). Tom qab cov qauv tsim, thaum lub teeb ci rau cov kab nqes hav ntawm ib lub kaum, ua kom muaj kev sib haum xeeb lossis yog li txo qhov kev cuam tshuam ntawm cov silicon wafer , uas yog, cuab ntxiab nyhuv (saib daim duab 2). Qhov zoo dua qhov loj me thiab kev sib txuam ntawm "qauv" qauv, qhov pom tseeb ntawm cov ntxiab nyhuv, thiab qis dua qhov chaw ntawm cov khoom siv cua silicon.

Daim duab 1: Micromorphology ntawm Monocrystalline Silicon Wafer tom qab ntau lawm

Daim duab 2: Lub teeb nres cov ntsiab cai ntawm "pyramid" qauv

Kev tsom xam ntawm ib qho Crystal ntxuav hniav dawb

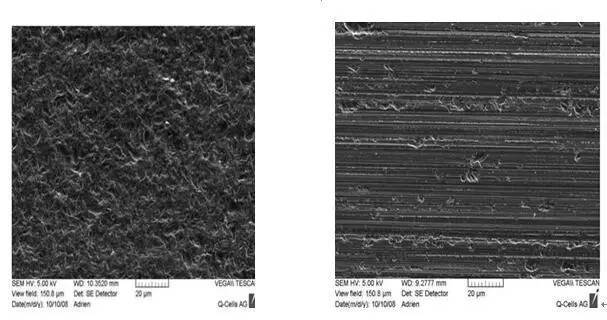

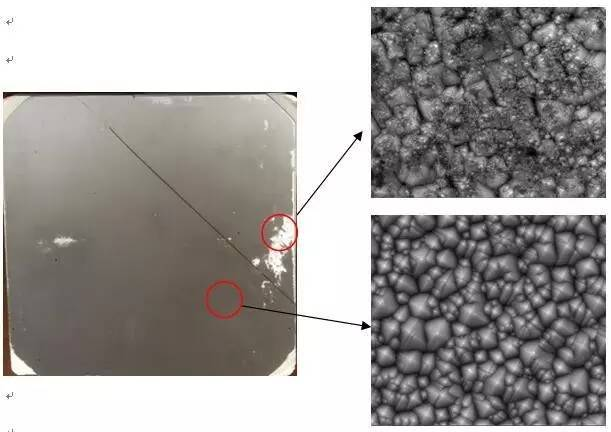

Los ntawm scanning Electron tsom rau cov khoom siv dawb silicon wafer, thiab cov npoo av ntawm "waxy" seem, thaum lub sij hawm pyramid ntawm Suede Hauv thaj chaw dawb ntawm tib cov wafer silicon tau tsim zoo dua (saib Daim Duab 3). Yog tias muaj cov seem nyob rau saum npoo ntawm monocrystalline silicon wafer, cov txheej txheem ntawm qhov chaw seem yog tsis txaus, ua rau muaj kev cuam tshuam zoo li cas yog qhov siab dua li qhov chaw ib txwm muaj, tus Thaj chaw uas muaj kev cuam tshuam ntau piv rau qhov chaw ib txwm muaj hauv kev pom ntawm dawb. Raws li tuaj yeem pom los ntawm kev faib cov duab ntawm cov cheeb tsam dawb, nws tsis yog ib txwm lossis ib txwm muaj nyob hauv thaj chaw loj, tab sis tsuas yog hauv thaj chaw hauv zos. Nws yuav tsum yog tias cov kuab paug hauv zos ntawm qhov chaw muaj wafefer tsis tau ntxuav, lossis cov xwm txheej ntawm cov wafer silicon yog tshwm sim los ntawm cov pa phem silient.

Daim duab 3: Kev sib piv ntawm cov cheeb tsam microstructure sib txawv hauv velvet dawb silicon wafers

Qhov saum npoo pob zeb diamond hlau txiav Silicon Wafer yog qhov muaj kev puas tsuaj loj dua (raws li qhia hauv Daim Duab 4). Piv nrog lub tshuaj khib silicon wafer, cov kev tawm tsam ceev ntawm alkali thiab lub pob zeb diamond txiav monocrystalline silicon wafer, yog li lub hwj cawv ntawm cov khoom seem ntawm Velvet nyhuv pom tseeb.

Daim duab 4: (A) Kev Cais Txoj Cai Ris Hlau Txiav Silicon Wafolr (B) Micrography Hlau Txiav Silicon Wafer

Lub ntsiab seem seem ntawm Pob Zeb Diamond Hlau-Nth Nthuas Silicon Wafer nto

(1) Lub ntsiab lus: Lub ntsiab ntawm pob zeb diamond xaim txiav cargactant yog surfactant, dispersant, defamagent thiab dej thiab lwm yam. Cov kev txiav ua kua nrog kev ua tau zoo tau raug tshem tawm kom zoo thiab ntxuav tau yooj yim. Surfactants feem ntau muaj cov khoom zoo dua hydroughilic, uas yog ib qho yooj yim los ntxuav tawm hauv cov khoom muaj wafer huv si. Kev txuas hniav ua kom txuas hniav thiab kev ncig ntawm cov tshuaj ntxiv hauv cov dej yuav ua npuas dej, thiab ua npuas ncauj kom muaj ntau yam teeb meem, uas yuav cuam tshuam rau kev siv. Yog li ntawd, tus coolant feem ntau yog siv nrog defojing tus neeg sawv cev. Txhawm rau kom ntseeg tau qhov kev ua yeeb yam defoaming, cov tsoos silicone thiab polyether feem ntau tsis zoo hydrophilic. Cov kuab tshuaj hauv dej yog yooj yim heev rau adsorb thiab nyob twj ywm ntawm cov nplaim dej silicon nyob rau hauv tu tom ntej, ua rau muaj teeb meem ntawm cov chaw dawb. Thiab tsis tau zoo nrog lub ntsiab ntawm lub coolant, yog li ntawd nws yuav tsum tau ntxiv rau hauv dej, hauv cov txheej txheem ntawm kev siv, raws li tsis taus cov xwm txheej ua npuas ncauj, tsis tuaj yeem tswj cov Siv thiab siv tshuaj tiv thaiv ntawm cov neeg sawv cev ntawm cov tub rog, nws tseem muaj kev cuam tshuam ntau dua, nws tseem muaj qhov tsis zoo ntawm cov khoom siv raw thiab defojing tus neeg sawv cev cov ntaub ntawv, yog li ntawd, feem ntau ntawm cov neeg caij nkoj hauv tsev cerantic txhua qhov siv cov mis no; Lwm lub coolant siv tus neeg sawv cev defoaming tshiab, tuaj yeem tiv thaiv nws tus nqi ntau, tuaj yeem tswj hwm tau yooj yim, muaj peev xwm tswj tau yooj yim, nrog kev ntxuav tu kom zoo, nws Cov seem tuaj yeem tswj tau cov qib qis, hauv Nyij Pooj thiab ob peb tus nqi khoom siv raw, nws cov txiaj ntsig tus nqi tsis pom tseeb.

(2) Cov kua nplaum thiab cov khoom siv Resin: Hauv cov theem tom qab ntawm lub pob zeb diamond hlau txiav, cov silicon wafer ntawm qhov hluav taws xob xaus yog tsis tau txiav los ntawm lub pob zeb diamond Hlau tau pib txiav rau cov roj hmab txheej thiab cov khaub ncaws hnav, nws cov khoom siv cob qhia yog tias ob qho tib si epoxy cov khoom siv ntawm cov roj hmab txheej lossis cov cob phaj yog tsawg, nws tuaj yeem yooj yim ua kom sov thaum lub sijhawm txiav thiab ua rau muaj cov kab hlau thiab yaj, ua kom muaj zog ntawm cov kab pob zeb diamond poob qis, lossis cov khoom siv silicon wafers tau txais thiab Stained nrog cob, ib zaug txuas, nws yog qhov nyuaj rau ntxuav tawm, cov kev paug no feem ntau tshwm sim ze ntawm ntug ntug ntawm cov silicon wafer.

(3) hmoov silicon: hauv cov txheej txheem ntawm pob zeb diamond hlau txiav yuav tsim kom muaj ntau yam silicon hmoov ntau, thaum cov hmoov loj heev, yuav ua raws li cov saum npoo si silicon, Thiab Pob Zeb Diamond hlau txiav ntawm silicon hmoov loj thiab loj loj rau nws yooj yim dua rau adsorption ntawm cov saum npoo si silicon, ua rau nws nyuaj kom huv si. Yog li no, xyuas kom meej qhov hloov tshiab thiab kev ua tau zoo ntawm lub txias thiab txo cov hmoov cov ntsiab lus hauv cov coolant.

(4) Tus neeg saib xyuas tu: Qhov kev siv pob zeb diamond tam sim no feem ntau yog siv cov xaim xaim, feem ntau yog siv cov hlau diamond, feem ntau, ib qho txheej txheem tu cov tshuab los ntawm kev ua mechanism los ntawm kev sib cav, ua ib Ua tiav cov kab, txias thiab muab cov txheej txheem kev ua kom huv, yog cov tshuaj ntxuav kom huv, thiab lwm yam yuav tsum yog rau kev hloov kho pob zeb diamond. Tu tus neeg saib xyuas yog ib qho tseem ceeb, tus thawj ntxuav kws tu suricon, yuav tsum yog rau kev ntxuav cov xov xwm sib dhos Txheej txheem ntxuav. Raws li tau hais los saum no, txoj kev sau qoob loo ntawm defoaming tus neeg sawv cev tsis xav tau nyob rau hauv coll txiav.

(5) Cov dej: Pob zeb diamond xaim txiav, dej ntxuav ua ntej thiab ntxuav cov dej muaj zog muaj cov impurities, nws yuav tau tshaj tawm rau saum npoo ntawm silicon wafer.

Txo cov teeb meem ntawm kev ua Velvet plaub hau dawb tshwm tawm tswv yim

(1) kom siv cov coolant nrog kev faib tawm zoo, thiab cov txias yog yuav tsum tau siv cov neeg sawv cev qis ntawm cov khoom seem ntawm cov khoom cua txias ntawm cov wafer ntawm silicon;

(2) Siv cov nplaum uas tsim nyog los txo cov pa phem ntawm cov wafer;

(3) Tus neeg txias txias yog diluted nrog dej ntshiab kom ntseeg tau tias tsis muaj cov khoom seem yooj yim hauv cov dej siv;

(4) Rau saum npoo ntawm pob zeb diamond xaim txiav Silicon Wafer, siv cov haujlwm thiab kev ua haujlwm tu kom haum;

(5) Siv cov kab pob zeb diamond cryant online rov qab los ntawm cov ntsiab lus ntawm silicon hmoov nyob rau hauv cov kab ke ntawm silicon hmoov ntawm silicon wafer deg ntawm cov wafer. Nyob rau tib lub sijhawm, nws kuj tseem tuaj yeem txhim kho kev txhim kho cov dej kub, ntws thiab lub sijhawm nyob rau hauv kev ntxuav ua ntej, kom ntseeg tau tias cov khoom sillicon yog ntxuav nyob rau lub sijhawm

(6) Thaum cov wafer silicon muab tso rau ntawm cov rooj tu, nws yuav tsum tau kho tam sim ntawd, thiab ua kom cov khoom muaj wafer silicon ntub dej thaum tag nrho cov txheej txheem ntxuav.

(7) Cov khoom wafer silicon ua rau cov nplaim dej nyob hauv cov txheej txheem ntawm degumming, thiab tsis tuaj yeem qhuav ib txwm. (8) Hauv cov txheej txheem ntxuav ntawm cov cua silicon, lub sijhawm raug txo kom deb li deb tau kom tiv thaiv cov paj ntau lawm rau ntawm cov nplaim dej silicon.

(9) Tu cov neeg ua haujlwm tu kom tsis txhob hu ncaj qha rau saum npoo Silicon thaum lub sijhawm ntxuav cov hnab looj tes, yog li tsis tsim cov ntiv tes luam ntawv.

(10) Hauv kev siv [2], lub roj teeb kawg siv cov kev ntsuas ntawm 1:26 (3% kev daws teeb meem), uas tuaj yeem txo qhov tshwm sim ntawm qhov teeb meem. Nws lub hauv paus ntsiab lus zoo ib yam li SC1 tu cov tshuaj (feem ntau hu ua kua 1) ntawm ib semiconductor silicon wafer. Nws lub ntsiab mechanism: Oxidation zaj duab xis ntawm silicon wafed nto yog tsim los ntawm oxidation los ntawm oxidation ntawm naoh, thiab oxidation thiab corrosion tshwm sim ntau zaus. Yog li ntawd, cov lus txuas nrog silicon hmoov, cob, hlau, thiab lwm yam) kuj poob rau hauv cov kua ntxuav nrog txheej corrosion; Vim yog oxidation ntawm H2O2, cov organic teeb meem ntawm Wafer saum npoo yog decomposed rau hauv CO2, H2O thiab muab tshem tawm. Tus txheej txheem no ntawm kev ntxuav tau cov khoom siv ua tus txheej txheem no los ua cov ntaub ntawv sib tsoo thiab Taiwan thiab lwm yam teeb meem roj teeb tsis txaus siab. Kuj tseem muaj cov roj teeb cov tuam txhab cov tuam txhab tau siv cov txheej txheem zoo sib xws, kuj tseem tswj tau cov tsos ntawm Velvet dawb. Nws tuaj yeem pom tau tias txoj kev ua kom huv no ntxiv rau hauv sillicon wafer tu cov txheej txheem kom zoo rau cov plaub hau ntawm cov plaub hau dawb ntawm lub roj teeb kawg.

tag

Tam sim no, Pob zeb diamond xaim txiav tau dhau los ua cov thev naus laus zis ntawm kev ua kom zoo nkauj Silicon wafer thiab roj teeb cov lag luam rau pob zeb tuam txhab diamond hlau tej silicon wafer muaj qee qhov tsis kam. Los ntawm kev txheeb xyuas thaj chaw ntawm thaj chaw dawb, nws yog feem ntau tshwm sim los ntawm cov seem ntawm qhov chaw ntawm cov wafer silicon. Txhawm rau kom tiv thaiv qhov teeb meem ntawm cov xov xwm silicon hauv lub cell, daim ntawv no ntsuas cov khoom muaj kuab paug ntawm cov tswv yim thiab kev ntsuas hauv kev tsim khoom. Raws li tus lej, cheeb tsam thiab cov duab ntawm cov pob dawb, cov ua kom pom tau thiab txhim kho. Nws yog qhov tshwj xeeb tshaj yog siv hydrogen peroxide + alkali ntxuav cov txheej txheem. Qhov kev ua tiav tau muaj pov thawj tias nws tuaj yeem tiv thaiv cov teeb meem ntawm pob zeb diamond xaim txiav cov tshuaj lom neeg uas muaj kuab lom thiab cov tuam ntxhab.

Lub Sijhawm Post: Lub Tsib Hlis-30-2024